Even so, the hole involving the pipe as well as flange may cause turbulence and force drops inside the piping technique.

Socket weld flange simplified as SW flange, it's a recessed place (like a shoulder) within the flange bore, this shoulder serves like a manual to established the depth on the pipe which is inserted to your flange. Socket Weld flanges were being at first designed to be used on tiny-dimension higher-stress piping.

SORF flanges are usually not as strong as SWRF flanges because of their fastened placement within the pipe and the lack of welding amongst the pipe as well as flange. SORF flanges are suggested for low-force and low-temperature apps.

The data provided In this particular website put up is meant for common informational needs only and really should not be construed as professional advice. When we strive to deliver precise and up-to-day information, we make no representations or warranties of any variety, Categorical or implied, with regards to the completeness, precision, dependability, suitability, or availability with the articles contained herein. Any reliance you put on the knowledge offered In this particular site write-up is strictly at your individual possibility. We disclaim any liability for almost any decline or harm, which include without the need of limitation, indirect or consequential reduction or destruction, or any reduction or injury whatsoever arising from reliance on information and facts contained During this site put up. We really encourage audience to validate the accuracy and relevance of any information introduced below with other resources and find professional suggestions or direction exactly where suitable.

Carbon Metal Socket Weld Raised Face Flanges offer you a lot of strengths when taking care of fluid programs because of ease of assembly/disassembly and elevated protection because of their capacity to generate tight seals among two components with no requiring added gaskets.

four) ✧˖° AI Inquiry Instrument: our AI-driven Resource features prompt and accurate responses to the complex and commercial queries. Our mission is to offer professionals in the EPC plant undertaking sector Along with the applications to excel.

Flanges are important to the piping system as they provide a relationship position for pipes, valves and fittings. Selecting the proper flange type is vital to effectively working and preserving the piping technique.

SWRF flanges have the next energy and durability because of the welding involving the pipe along with the socket, which presents additional security and assistance for the piping program. swrf socket weld raised face flanges SWRF flanges are proposed for top-pressure and substantial-temperature applications.

Tolerance: The tolerance on the bore diameter ensures the flange won't impede fluid flow or result in too much turbulence. The tolerance commonly allows for a slight clearance in excess of the surface diameter of your pipe, making sure a in good shape that facilitates welding with no extreme gap or interference.

Socket weld raised face flanges undoubtedly are a trustworthy and efficient way to manage fluid programs, but more goes into the choice method than simply dimension and substance.

There's also threaded socket weld raised face flanges with threads on the two ends for simple relationship. You'll find blind socket weld raised face flanges with only one opening for connecting with A different component or gadget. Differing types of items are offered, such as Monel 400 Flanges, Inconel X750 Flanges, and many others.

SORF Flange is really a style of flange Employed in pipe fitting. It really is an integral Portion of the piping technique and keeps pipes linked securely. SORF means Slip on Raised Face, indicating that the face on the flange bolts to your raised face about the mating pieces.

SWRF flanges will be the more expensive solution as a consequence of the extra labour and knowledge linked to their set up.

Adherence to those tolerances is important for your performance and integrity of the socket-weld flange connections. The correct implementation makes certain proper alignment, weld high-quality, and sealing performance, contributing to the security and dependability of the general piping method.

* Industry Insights: Updates on the latest trends, technologies, and regulatory changes impacting the industries lined. * Guides And the way-Tos: Sensible suggestions on picking out the correct materials and devices for specific programs, and also tips about installation, upkeep, and troubleshooting. * Security and Expectations: Info on protection machines for output web pages, chance mitigation methods, and an summary of suitable business specifications and regulatory frameworks. The web site is built to help the Experienced growth of engineers, procurement experts, job managers, together with other stakeholders associated with job plant organizations, by disseminating crucial know-how and best practices. Regardless of whether readers are new to the field or seasoned industry experts, weblog.projectmaterials.com delivers methods to improve their knowing and general performance in running undertaking products proficiently. Do you have to desire to succeed in out into the author of this text, we invite you to Call us by means of e-mail.

Alternatively, SORF flanges slide onto the pipe and so are fastened set up with fillet welds. This design and style permits simple and fast set up, as well as the essential expert labour is minimum.

SWRF flanges Use a socket at the base of the flange that fits the pipe, along with the welding is completed involving the pipe along with the socket. This design and style makes certain a easy and uniform transition concerning the pipe and also the flange, which cuts down turbulence and stress drops from the piping procedure. The installation of SWRF flanges is time-consuming and involves competent labour.

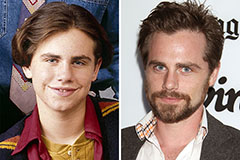

Rider Strong Then & Now!

Rider Strong Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now!